Salem’s Canneries

“At harvest time there could be so many sacks of beans waiting to be processed that Marion Square Park would be used as a storage spot with sacks covering the ground under the trees.”

One of the first fruit processing operations in the Willamette Valley was the cider and vinegar works which Gideon Stolz established in Salem in 1879. He never engaged in fruit and vegetable canning but his cider and vinegar works was Salem’s largest and most important early business dealing with the manufacture and preservation of food products. He operated the business on his own for a number of years but then entered into a partnership with two Portland businessmen and in 1886 incorporated as Pacific Cider, Vinegar, & Fruit Preserving Company. They were located on Trade Street opposite Cottage and used the millrace. A pickle operation was added in 1889 and by 1890 they were producing vinegar, cider, pickles, and fruit jellies, syrups, and butters. The company relocated to Portland in 1891, and the Salem plant was sold to Squire Farrar & Company, and later to Tillson & Company in 1903, and Drager Fruit Company in the 1920’s. The packing plant, warehouse and equipment were destroyed by fire in 1928. It is interesting that in 1894 Gideon Stolz himself sold his interest in the Pacific Cider operation in Portland and came back to Salem to start a new pickle and cider factory in 1897 on Summer Street between Mill & Bellevue. In addition to his former products, plus mincemeat, catsup, mustard, Worcestershire sauce, horseradish, and sauerkraut, he had a bottling line for soda beverages. He operated as Gideon Stolz Company under the “G.S.” label. In the 1930’s & 40’s many of the products were discontinued as more emphasis was placed on beer and wine. The factory site was purchased by Willamette University in 1965 and is now occupied by student housing units and tennis courts.

1958, Display of tins of Au Franc products – Plum Jam, Strawberry Preserves, Wild Blackberry Preserves, Red Raspberry Jam, Boysenberry Jam, Apricot-Pineapple Preserves

Envelope reads: McEwan’s No. 2097. Au Franc Date 6/20/58. 2 8×10 gl 55c, 2006.002.2097

In 1885 Robert S. Wallace arrived in Salem and was instrumental in securing land on a corner of the Willamette University campus, opposite the Thomas K. Woolen Mill, for the development of a fruit evaporator. The shape and location of the site provided rail car loading on two sides, access to the millrace crossing the property, and frontage on 12th Street. It was about one acre in size and cost $500. The Willamette Valley Fruit Company’s dryer was built there in 1887 and in 1890 Robert S. Wallace formed the Salem Canning Company and built a cannery adjoining it. Tomatoes, peas, corn, beans, cherries, black raspberries, plums, pears, and apples where among the products marketed under their “Thistle Brand” name. In 1890, the stockholders realized a return of almost $5,000 on their original $20,000 investment. Mr. Wallace died unexpectedly the following year and several factors caused the company to be sold. It operated under the Allen name briefly and as Oregon Packing Company from 1902-1905 when it burned. Following the fire, local growers who relied on the cannery as their sole market, were served for four years in a cooperative effort by the Mutual Canning Company, but in 1910 the California Fruit Canners Association secured ownership and brought to an end local ownership of Salem’s first cannery. Oregon Packing Company continued operating under that name in a Southern Pacific warehouse near the railroad station until 1935, but as a subsidiary of California Packing Corporation (which it had become in a 1916 merger). In 1935 it was absorbed into the parent company and became known as Calpak Plant #126. The site of the original cannery from 1887 is now the location of a parking lot on the Willamette University campus.

The depression years of the 1930’s was a hard period for canneries. With unemployment so common and no money to buy commercially canned food, most families canned their own fruits and vegetables. Growers were left with no market for their crops; loganberries might bring one to two cents a pound, strawberries – four cents , Royal Anne cherries – two to three cents. To provide for the large surplus of cherries, brining operations were established and the bleached, pitted product was sold to maraschino manufacturers in the East. As the Depression deepened a portable cannery was established and made available to the public for canning their own produce. Seed was given out by the Red Cross, cans were furnished by the government, and the cannery, installed on a truck bed, moved from town to town allowing people an allotment of 25 & 50 cans per person in 1933 and 1934 respectively.

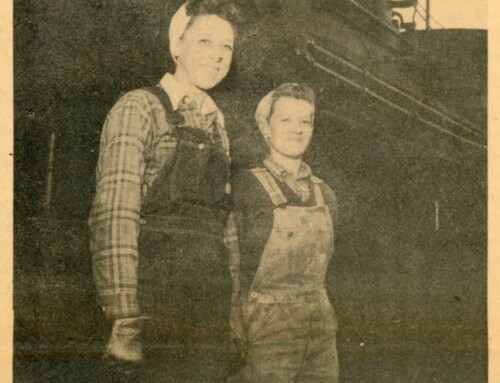

In the 1940’s, when the canneries were frequently short of help because the men were away at war or wartime industries, many people worked their regular job during the daytime and also worked the night shift at the canneries; offices let people out early in harvest season so they could work in the fields, and soldiers even came from nearby Camp Adair to help out. Young people looked forward to being able to advance from picking berries, beans, hops, etc. in the fields to working in the canneries when they became sixteen. Cannery work was hard but it gave them money for clothing and for school in the fall. At harvest time there could be so many sacks of beans waiting to be processed that Marion Square would be used as a storage spot with sacks covering the ground under the trees. In the late 1940’s there were 15 canning and freezing plants in Salem alone with many more in surrounding towns. The soil & availability of irrigation, the warm days and cool nights, the stable workforce, and the long and successful history of quality fruits, berries and vegetables all contributed to the explosion of canneries in the Salem area. In the 1950’s the Salem area replaced San Jose, California, as the largest canning area in the world. A wartime shortage of tin plate and the need for large quantities of the canned product for the armed forces made the frozen product an important alternative for the civilian market.

In July 1943 Salem joined the ranks of other communities which developed school community canneries to conserve locally-grown food for civilian usage and allow commercial canneries to pack for military needs. The cannery facilities, with certain limitations, were available to local farmers, Victory gardeners, and anyone else with produce which they wanted to process. Patrons brought their produce in by appointment, and the canning was done under an expert’s direction and was safely processed in tin cans under highly controlled cooking facilities; it thus took the drudgery of canning at home away from the busy housewives. Oregon’s eleven community school canneries were entirely non-profit and publicly financed with the only cost to the patron being six or seven cents a can, depending on size.

Ed Austin, 1984, DelMonte Cannery Building -long metal sheathed building, painted green and white standing parallel to railroad tracks and powerlines. Along long side is a cement ramp and loading dock as well as a series of doors and windows. This building stood opposite Salem Main train depot prior to building of TIUA structures that now (2016) stand there. Image is taken from the depot platform looking to the south east from the northwest corner of the building. Donor believes building may date back to S.P. Hops warehouse that also stood on the site., 2016.019.0008

The canneries described below are only a few of the many which existed in Salem over the years, with their managements and names changing frequently. The fertile soil of the Willamette Valley and Salem area produced ample fruits and vegetables for all and, although some canneries gained recognition for particular products, e.g. Blue Lake for their pole beans, all produced a broad range of products.

The Salem Fruit Union was formed and built a 2-story wooden building on the SE corner of Trade & High streets in 1910 with rail access to both the Southern Pacific & Oregon Electric. When the Hunt Brothers Packing Company built a cannery on the river at the foot of Division Street in 1914 the Fruit Union sold their canning line to the latter and concentrated on packing and marketing fresh and dried fruit, and loganberries in various forms. In 1920 the Salem Fruit Union was absorbed into the Oregon Growers Association, but the latter dissolved in 1923. The last of the Salem Fruit Union plant was razed for part of the Pringle Park Urban Renewal Project in the 1970’s.

The Hunt Brothers Packing Company mentioned above expanded their one-story wooden building on Front Street in 1924 & 1925 and again in 1929 when they added a 2-story office building on Division Street. The cannery closed at the end of the 1956 season at a time when it had 16 permanent and 400 seasonal employees. The location was acquired by the Keith Brown Lumber Company which is still operating at that location.

Running northward from North Mill Creek along Front Street and the river was a cannery which over the decades had many name changes. It was known as Salem King’s Products Company from 1917-1927. In 1929 Reid Murdock & Company, the largest wholesale grocery distributor in America, bought the plant and acquired more land in the area. All evaporating equipment was removed and extensive remodeling was accomplished for canning. They were a major supplier of canned fruit to the Armed Forces during World War II. More recently the plant was known as United States Producers from 1973-1975, and since then as Truitt Brothers. When Truitt Brothers acquired the plant they began a modernization program which made the 60-year old plant one of the most efficient operations in the Northwest. They diversified their line of products, acquired still more land, and with efficient, stainless steel production lines are able to produce a high-quality product with a minimum of hand labor. They are now among Oregon’s top 100 private businesses.

A long association with the name “Blue Lake” began when the first Blue Lake beans were planted in 1923 and the variety captured over thirty percent of the canned green bean market. Blue Lake Producers Cooperative was begun in 1937 as a reorganization of another company and operated out of a plant in West Salem. It was one of three companies in Salem authorized to provide dehydrated vegetables and fruit to the military. The name was changed in 1946 to Blue Lake Packers and produced under many labels, including “Jack and the Beanstalk”. Their beans received considerable publicity from association with Lou Costello when he and Abbott made a movie by that title in 1952. Both the movie and Blue Lake’s beans were promoted at grocery stores and restaurants and Costello had over forty cases of the beans sent to his journalist and radio commentator friends. By 1970 their sale were $12,000,000 and ninety percent of their production was canned and ten percent frozen. They had twenty different products and their plants had undergone several expansions. The company became part of Agripac, Inc. in 1971 which has expanded operations into eastern Washington.

Another name synonymous with canning in Salem for over fifty years was Paulus. Three of the six sons of Elizabeth and Christopher Paulus had careers in canning. Robert C. Paulus, the first of the brothers to enter the canning field, started Robert C. Paulus & Company in 1924 after having gotten several years experience working with other companies. For their early operations they leased from other canneries, but in 1927 Paulus Bros. Packing Company was organized by he and his brother George. When they added beets, parsnips, and carrots to their line in 1927 it was the first time vegetables in any quantity had been caned in Salem. Their earlier production was concentrated mostly on gooseberries, strawberries, loganberries, sweet cherries, raspberries, blackberries, pears & purple plums. In 1942 Paulus Bros became one of three Salem companies authorized to provide dried fruits and vegetables for the armed forces and they leased additional canning and dehydration plants.

Their contributions to the war effort brought them awards for outstanding accomplishment as a food processor. From their early quarters on High Street they expanded and soon had plants in other cities, and in 1946 built a new cannery at 14th & Oxford Streets, one of the largest in the United States. Following World War II in November 1950 they packaged C-6 Army food rations that had been designed by the quartermaster corps for American troops engaged in combat. The 321 women and 86 men worked round-the-clock in three shifts. The C-6 package was designed to sustain a soldier for emergency use in battle (900 calories) and included meat and fruit items. In 1954 they were the largest independently owned canning firm in the Northwest, and the sale of the company in 1955 to Dole Hawaiian Pineapple Company marked the end of an era. Berries, cherries, green beans, plums and pears were the principal products from the Dole plant in the 1950’s-60’s. The canning operation begun by the Paulus family ended in 1985 and canning operations ceased but the building is still used for distribution.

Researched and written by Joan Marie “Toni” Meyering

Bibliography:

Lucas, William. Canning in the Valley: Canneries of the Salem District. 1998

“Paulus Bros. Busy Packing Ration Kits”, Capital Journal newspaper, November 24, 1950

“V-Garden Products March into Cans In Dozen Oregon Community Kitchens”, Oregon Journal newspaper, August 8, 1943.

This article originally appeared on the original Salem Online History site and has not been updated since 2006.

Leave A Comment