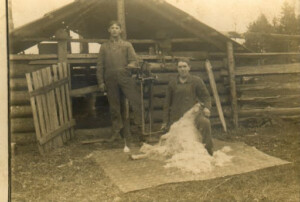

Woolen Mills

1908, Sheering Sheep, April 13, 1908. Two men in front of sheep shed with equipment and sheep and wool on blanket. reverse side is postmarked April 13 in Marion and April 4 in Turner. Addressed to “Miss Sillie Fullows” at RFD #2, Turner., WHC Collections 1986.003.0012.023

The first woolen mill in Salem was the Willamette Woolen Mill, built near the confluence of the Willamette River and North Mill Creek. The history of the company begins in 1847 when Joseph Watt, one of Salem’s early settlers, returned to the Midwest and persuaded his family to emigrate. Three hundred thirty of the 400 sheep the family drove westward survived, and Watt joined with John Minto, Dan Waldo, and Reynolds to form the company. The mill was to be built wherever the first $9,000 worth of shares could be obtained. Salem put up the additional $2,000 to its already committed $7,000 and won out over Polk and Yamhill counties. John D. Boon donated the land, and the rights to bring Santiam River water from Stayton through the Salem Ditch were negotiated.

Joseph Watt was a skilled carpenter and supervised construction of the building. R. E. Pratt from Worcester, Massachusetts was asked to help select the equipment and then come out and run the mill. A gala ball was held November 19, 1857 preceding the installation of machinery in the building. They had dinner, dancing, speeches, and fired a cannon to announce the raising of the flood gates to allow the first water through. It was the first power-operated woolen mill on the Pacific Coast. The first blanket woven was auctioned for $250, and bore a label that read “Hardtimes.” This turned out to be prophetic. In 1858 sales did not go well, payrolls were not met, the company was deeply in debt and there was talk of shutting it down. Pratt pulled it through by employing such unconventional practices as using barter as a method of payment and issuing factory scrip for pay. Bad management ultimately did wreck the business, and a fire May 3, 1875 destroyed it. The mill had been Salem’s leading industry for almost twenty years and employed 100 people.

Salem did not have another woolen mill until Thomas Lister Kay, Squire Farrar, and C. P. Bishop founded the Thomas Kay Woolen Mill. In 1889 they responded to an offer from Salem civic and financial leaders to subsidize building a mill. A site was chosen at the earlier location of the Pioneer Oil Company near Twelfth and State streets in Salem. Kay traveled to England to see what improvements had been made in technology and the equipment for the new mill was ordered to his specifications. Three fire hydrants were even installed to guard against fire and the mill boasted the first overhead sprinkler system in an entirely wood structure.

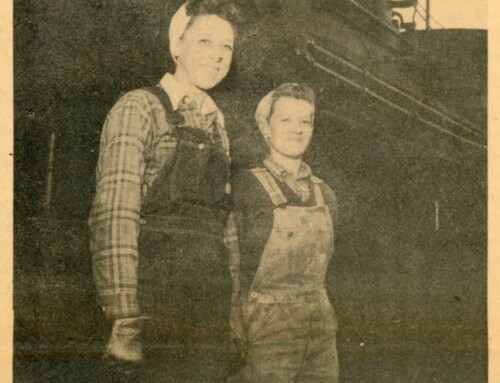

Catterlin, B&W photo of Thomas Kay Woolen Mill Co. with workers standing and sitting in front of the building. Photograph of original Kay Mill built 1889., WHC Collections M3 1974-015-0007a

Mr. Kay had learned his skills in his teens in Leeds, England, and applied much of what he learned there to the new Salem mill. The old-country skills, passed along to new workers through apprenticeship programs, soon showed up in our newly founded mills with competently trained textile workers and supervisors. The more competent workers took over as managers and left the routine work to others. Thus the operations at our mills reflected not only the technology but also the managerial style of the old country. At $4.50 a day, the boss dyer was the highest paid mill worker . Three members of the Bishop family, who later started Pendleton Woolens, worked at the Kay Mill, and one of them opened a store on the premises in 1891. The Salem Woolen Mills Store became the leading men’s clothing store in Salem.

The mill burned in 1895* at a loss of $90,000, $55,000 of it Kay’s own money. The fire department’s operations were criticized. At a large public meeting, Kay was given a vote of confidence to rebuild and most of the necessary subsidy was raised.

The present mill building was designed by Walter Pugh the following year and was patterned after another Kay mill which the company had acquired at Waterloo in Linn County two years earlier. Rock from the old mill was used in making the two-foot thick stone and concrete foundation walls nine feet high. The brick walls above the first floor are seventeen inches thick, and above the second, twelve inches thick. The immense floor timbers are 60 feet long with planks and flooring on top of that.

The mill, with 88 employees, produced the first bolt of worsted goods west of the Mississippi in November 1896, and had twenty-eight looms operating by 1915. In the early days the mill concentrated on making mackinaws and flannels while the Waterloo mill made bed and camp blankets. In the late 1940s, seventy- five percent of their raw wool was purchased directly from Willamette Valley farmers and their 115 employees produced finished suiting, flannels, cashmeres, tweed and blankets.

The mill operated on the gravity principle, as did many other mills. The first procedures were done on the third floor. Then, the wool was dropped through a trapdoor to the second floor for the next step, then dropped through to the main floor where the finishing was done.

The entire operation was run by water power from the millrace which can be seen entering the mill at a higher level. Through a system of wheels, gears, belts and turbines, water ran the machines. The flow of the water was regulated by gates at the entry so the machines ran at an even, steady pace which was crucial to the quality of the wool. A generator was installed in the 1940s and surplus electricity is sold back to Portland General Electric. The water seen rushing down the incline outside is simply excess and joins the other water later. The scope of the operation was second only to that of the mill in Oregon City on the entire West coast. It is a unique example in the Pacific Northwest of the industrial type plant based on English and Atlantic seaboard models. It is one of a few plants in North America able to demonstrate an entire manufacturing process by direct drive water power.

The mill was under continuous ownership and management of the Kay family until it was sold to the Mission Mill Museum Association for $160,000 in 1965, after having been closed for three years. The Mission Mill Association has restored it to show authentic manufacturing processes from the time, and to depict the industrialization of America.

Written by Joan Marie “Toni” Meyering

Bibliography:

Capital Journal, January 6, 1951.

Lomax, Alfred L. “Pioneer Woolen Mills in Oregon,” Oregon Historical Quarterly, 30/2, (June 1929): 147-160.

Nomination papers for the National Register of Historic Places Inventory by Elizabeth Walton Potter.

Robertson, James R. “A Pioneer Captain of Industry,” Oregon Historical Society Quarterly, IV/3, 1903, 162-167.

Salzmann, Joan Marie “Toni”, “Salem’s Creeks”, Marion County History, School Days II, 14, 1983-84, 3-9.

“Thomas Kay Woolen Mill Goes Back 60 Years”, Capital Journal, 20 January, 1949.

Thomas Kay Woolen Mill Museum: an Experience in History (brochure).

This article originally appeared on the original Salem Online History site and has not been updated since 2006.

*The source of this date of the fire comes from Alfred L. Lomax’s book Pioneer Woolen Mills In Oregon (Binfords & Mort, 1941). Lomax’s date appears to have had a typo in it. The fire took place in 03 May 1876. There is no newspaper evidence for a fire at the plant in 1875, but there is in 1876. See “Destruction of Salem Woolen Mills” Willamette Farmer 05 May 1876 pg 5 available online through the Historic Oregon Newspapers Site: https://oregonnews.uoregon.edu/lccn/sn85042522/1876-05-05/ed-1/.

Leave A Comment